Savings

The water monitor float switch manufactured by DDPumps will save you money by reducing energy usage, as it ensures pumps run only when necessary. This is especially important because compressed air is expensive to generate, and avoiding unnecessary pump operation helps lower your energy costs significantly. By automatically detecting high or low water levels, the float switch prevents wasted energy, reduces wear on equipment, and helps avoid overflows, dry running, and costly maintenance or repairs. Built for durability and low maintenance, the DDPumps water monitor float switch provides long-term savings through efficient water management and extended equipment life.

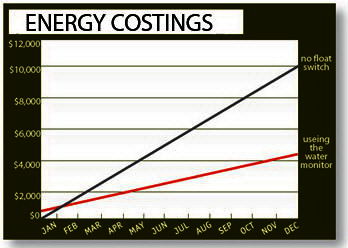

| The WATER MONITOR pneumatic float switch is wholly designed and manufactured in Australia to comply with stringent coal mining regulations. In industrial settings where precise liquid level control is crucial for safety and operational efficiency, float switches play a vital role. they are commonly used in sump pumps, cooling systems and chemical processing plants to prevent overflow or dry running pumps. Hundreds of WATER MONITORS in Australia and overseas are in service giving huge savings. One particular mine after installing WATER MONITORS noted that a particular pump had dropped from 24/7 operation to 25 minutes a day. Many WATER MONITORS have gone into industrial situations such as waste water sumps. Another use where spillage was a problem the WATER MONITOR was modified and turned upside down and mounted on the tank so as to turn the pump off when the tank was full. | Possible Savings by using a monitor float switchNote the graph below shows projected savings over a 12 month period when a water monitor float switch is used, resulting in a 60% reduction in pump running time.

Enquire Now |